ENGINEERED FLOORING

OUR ENGINEERED FLOORING

Engineered flooring boards should not be confused with far inferior laminates. They consist of a cross bonded backing for added stability and a thick wear layer of oak, making them indeterminable from solid boards once fitted. Although originally innovated for use with under floor heating, engineered Oak and Walnut boards are now often specified in situations where a solid board would have been appropriate as they are easier to fit, (can be floated, glued or nailed). Engineered flooring can also be used straight from the pack, as its stability means it requires no time to adjust to room temperature. Our engineered flooring is supplied in mixed grade packs which incorporate Prime, Character and Rustic grades.

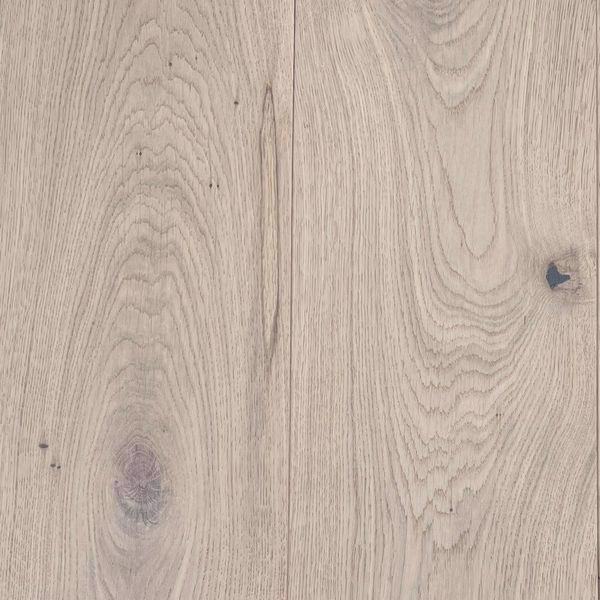

ROUND WOOD Engineered Oak Floor Board – Brushed, White-oiled

£42.75 m2 + VAT (£51.30)

CAMDEN OAK Engineered Oak Herringbone Parquet – UV-oiled

£32.50 m2 + VAT (£39.00)

GENERAL’S HOUSE Engineered Oak Floor Board – Distressed, Pre-oiled

£114.00 m2 + VAT (£136.80)

SHUSTOKE FARM Engineered Oak Floor Board – Distressed, Wax Oil

£114.00 m2 + VAT (£136.80)

VINTAGE COLLECTION EALDWINE Engineered Oak Floor Board – Smooth, Pre-oiled

£157.50 m2 + VAT (£189.00)

ROUND WOOD Engineered Oak Floor Board – Brushed, Pre-oiled

£39.95 m2 + VAT (£47.94)

ROUND WOOD Engineered Oak Floor Board – Smooth, Natural-oiled

£47.00 m2 + VAT (£56.40)

ROUND WOOD Engineered Oak Floor Board – Smooth, Pre-oiled

£39.55 m2 + VAT (£47.46)

ROUND WOOD Engineered Oak Floor Board – Smooth, Untreated

£43.26 m2 + VAT (£51.91)

ROUND WOOD Engineered Walnut Floor Board – Smooth, Pre-oiled

£40.50 m2 + VAT (£48.60)

ORKNEY SHORE Engineered Oak Floor Board – Smooth, HD Natural-lacquered

£153.00 m2 + VAT (£183.60)

TREVITHICK Engineered Oak Floor Board – Saw-marked, Pre-oiled

£162.00 m2 + VAT (£194.40)

ROUND WOOD Engineered Oak Floor Board – Brushed, Invisible-lacquered

£55.00 m2 + VAT (£66.00)

ROUND WOOD Engineered Oak Floor Board – Brushed, UV-lacquered, Colour 4

£45.00 m2 + VAT (£54.00)

ROUND WOOD Engineered Oak Floor Board – Brushed, Saw-Marked, Wax-oiled, Colour 9

£35.10 m2 + VAT (£42.12)

ROUND WOOD Engineered Oak Floor Board – Brushed, UV-lacquered, Colour 3

£45.00 m2 + VAT (£54.00)

ROUND WOOD Engineered Oak Floor Board – Brushed, Saw-marked UV-lacquered, Colour 8

£45.00 m2 + VAT (£54.00)

ROUND WOOD Engineered Oak Floor Board – Brushed, Untreated

£46.40 m2 + VAT (£55.68)

ROUND WOOD Engineered Oak Floor Board – Brushed, UV-oiled

£39.95 m2 + VAT (£47.94)

ROUND WOOD Engineered Oak Herringbone Parquet – Brushed, Smoked, White-oiled

£32.00 m2 + VAT (£38.40)

ROUND WOOD Engineered Oak Floor Board – Distressed, Wax-oiled, Light Antique Brown

£60.75 m2 + VAT (£72.90)

BOASLEY Engineered Oak Herringbone Parquet – UV-oiled

£59.95 m2 + VAT (£71.94)

ALBANY Engineered Oak Herringbone Parquet – UV-oiled

£61.50 m2 + VAT (£73.80)

RICHMOND Engineered Oak Herringbone Parquet – UV-oiled

£51.25 m2 + VAT (£61.50)

RATTON Engineered Oak Herringbone Parquet – Grey-limed

£51.25 m2 + VAT (£61.50)

ALBUS Engineered Oak Herringbone Parquet – Ice White

£51.25 m2 + VAT (£61.50)

SUTTON Engineered Oak Herringbone Parquet – UV-oiled

£51.25 m2 + VAT (£61.50)

OAKLAND Engineered Oak Herringbone Parquet – UV-oiled

£51.25 m2 + VAT (£61.50)

HELLINGLY Engineered Oak Herringbone Parquet – UV-oiled

£44.96 m2 + VAT (£53.95)

FRESNO Engineered Oak Herringbone Parquet – UV-oiled

£46.25 m2 + VAT (£55.50)

NAPA Engineered Oak Herringbone Parquet – Ice White

£46.25 m2 + VAT (£55.50)

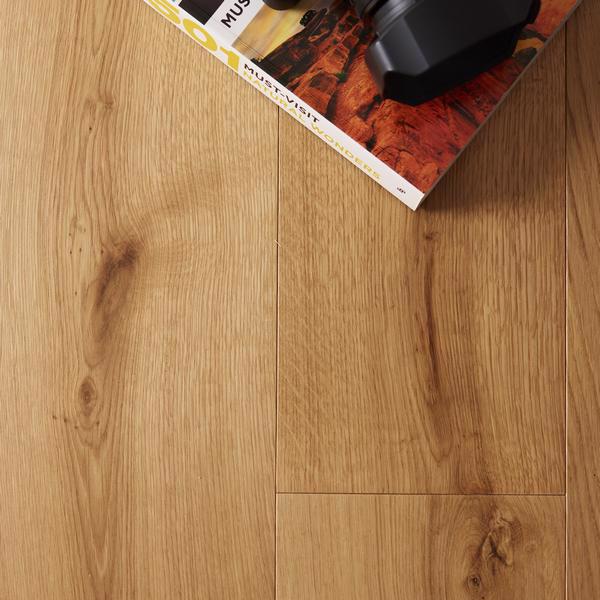

NORTHIAM Engineered Oak Floor Board – UV-oiled

£50.95 m2 + VAT (£61.14)

EPNEY Engineered Oak Floor Board – UV-oiled

£52.95 m2 + VAT (£63.54)

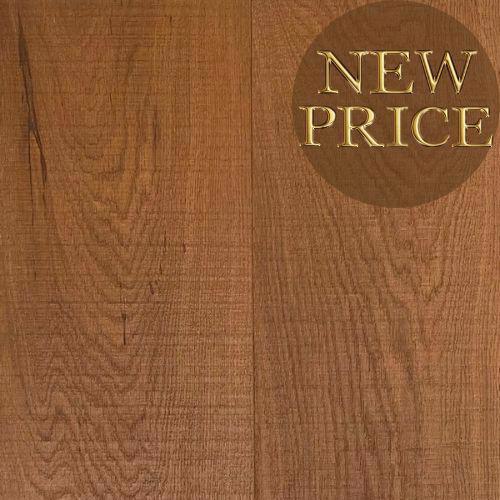

CHELDON Engineered Oak Floor Board – Cognac-stained, Oiled

£53.95 m2 + VAT (£64.74)

FARWAY Engineered Oak Floor Board – UV-oiled

£59.95 m2 + VAT (£71.94)

CLEVELAND Engineered Oak Floor Board – Matt Lacquered

£55.45 m2 + VAT (£66.54)

YSTAD Engineered Oak Floor Board – UV-oiled

£55.45 m2 + VAT (£66.54)

LEXINGTON OAK Engineered Oak Herringbone Parquet – Unfinished

£30.60 m2 + VAT (£36.72)

BEAUMONT OAK Engineered Oak Herringbone Parquet – UV-lacquered

£30.60 m2 + VAT (£36.72)

HUDSON OAK Engineered Oak Herringbone Parquet – UV-oiled

£32.50 m2 + VAT (£39.00)

ASHEVILLE OAK Engineered Oak Herringbone Parquet – Invisible-oiled

£32.50 m2 + VAT (£39.00)

AUBURN OAK Engineered Oak Herringbone Parquet – UV-oiled

£46.75 m2 + VAT (£56.10)

ROCKPORT OAK Engineered Oak Herringbone Parquet – UV-oiled

£46.75 m2 + VAT (£56.10)

HARBOR OAK Engineered Oak Herringbone Parquet – UV-oiled

£53.60 m2 + VAT (£64.32)

BLUE RIDGE OAK Engineered Oak Herringbone Parquet – UV-oiled

£53.60 m2 + VAT (£64.32)

PRESCOTT OAK Engineered Oak Herringbone Parquet – UV-oiled

£53.60 m2 + VAT (£64.32)

BELLINGTON OAK Engineered Oak Floor Board – UV-oiled

£35.70 m2 + VAT (£42.84)

RALEIGH OAK Engineered Oak Floor Board – UV-oiled

£35.70 m2 + VAT (£42.84)

MONTPELLIER OAK Engineered Oak Floor Board – Unfinished

£39.00 m2 + VAT (£46.80)

MADISON OAK Engineered Oak Floor Board – UV-lacquered

£40.80 m2 + VAT (£48.96)

FAIRMONT OAK Engineered Oak Floor Board – UV-oiled

£40.80 m2 + VAT (£48.96)

CHARLESTON OAK Engineered Oak Floor Board – UV-oiled

£40.80 m2 + VAT (£48.96)

GREENVILLE OAK Engineered Oak Floor Board – UV-lacquered

£40.80 m2 + VAT (£48.96)

HARTFIELD Engineered Oak Floor Board – Matt Lacquered

£46.25 m2 + VAT (£55.50)

WHY ENGINEERED FLOORING?

Oak flooring is a valuable enhancement to any development, regardless of style. Traditionally, solid boards have proven popular given the look and durability they provide. Of late, however, engineered alternatives are increasingly in demand at the top end of the market. Engineered boards should not be confused with far inferior laminates. They are far more durable, attractive, authentic and indeterminable from solid boards once fitted, given that they consist of a chunky wear layer of oak. This is supported by a thick multi-ply backing that is cross bonded for added stability, helping to reduce the board’s tendency to shrink and expand, even in environments with a high degree of temperature variance. Whilst its innovation arose out of the need for a quality oak board suitable for use with underfloor heating, engineered flooring is now fitted in an increasing number of situations. It can be laid in damp prone environments where traditional flooring would not have been appropriate and, as it requires no time to adjust to room temperature, can be used straight out of the box for late notice projects. It is also easy to fit.

Engineered boards can be floated directly over an underlay, without the need for bonding or nailing. This doesn’t sacrifice durability and still provides that solid underfoot feel, particularly when a 21mm thick board is used. Given these factors, it is no surprise that engineered boards are increasingly specified, even when solid is a viable option. The majority of engineered flooring is supplied pre-oiled. This is the wise choice as it permits small areas to be treated at a time for damage, unlike a lacquer which can require an entire floor to be re-finished. Engineered floors also allow for multiple sandings, with wear layers that typically vary between 3mm and 6mm depending on price. Widths of a board vary widely to accommodate a wide range of tastes. The widest board we offer measures 300mm in width. Whilst there is no hard and fast rule as to the appropriate choice, the commonly held belief is that the wider the room, the wider the board that should be used. In practice, however, personal preference is the best guide.

GET IN TOUCH

Looking for advice or have a question? You may find the answer in our FAQs here. Alternatively, fill out our quick form below and we’ll put you in touch with the right person in our team! We’ll get back to you by the end of the next working day.